- Phone: (616) 457-1212

- Fax: (616) 457-3620

Custom Applications

Gluco, Inc. design engineers have successfully developed and delivered numerous custom applications that competitors have turned away. Following is a sampling of the machinery we have placed.

Metal Injection Molding

Though only a 25 ton clamp force this machine needed oversized inject cylinders and an ultra hard injection unit to deliver the highly abrasive Tungston Carbide material. Let our engineering department have a look at your next metal or ceramic injection molding application.

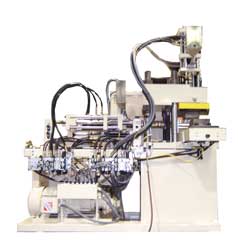

Multi Color/Material

With our unique clamping system the upper injection molding. This machine has one vertical and one horizontal injection unit with a left/right shuttle on a “C” frame press. It’s purpose is for added versatility in a laboratory prototyping or production environment.

Hydraulic Presses

Gluco’s expertise in hydraulic motion control makes it easy for us to build hydraulic presses up to 200 ton for almost any application. Contact Gluco for pricing on your next trimming, forming, laminating, die setting or compression molding application. Refurbished Presses.

Refurbished Presses

If a new machine just doesn’t fit within your budget you may want to consider having yours rebuilt. In most cases you get your machine returned to you in a like new condition with all of the latest hydraulic and electrical control